Project “Strengthening the competitiveness of A-elektronik by investing in a digital and green transition”

when you can innovate?

A-Elektronik is engaged in research, development and production in the field of embedded technologies, real-time operating systems, machine learning, artificial intelligence, mechanical engineering and mobile applications.

Check out our company video

Our services

Research and development of electronic products

The best reference for our research and development department is the fact that we own as many as 15 international technology patents. For now. So if you have a new challenge for us, we would love to listen to you. From the first design, through 3D models, prototypes, laboratory and field tests to the final product, you can count on a top result – because our experienced engineers will never agree to anything less.

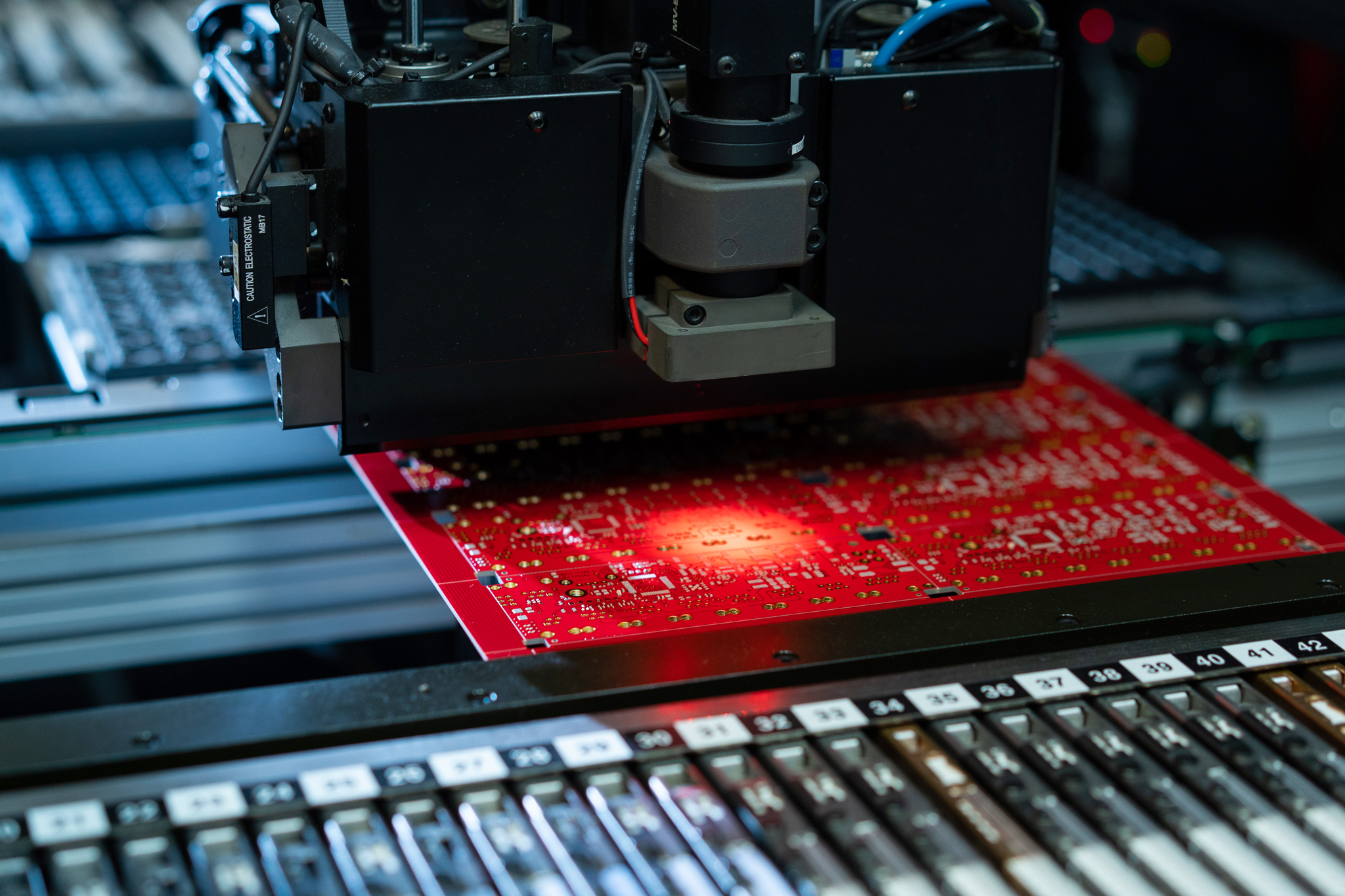

SMT assembly service

In addition to research and development, we also offer SMT assembly services. From prototypes to small and medium production series, we have the capacity for more than ten thousand printed circuit boards per year. If you are one of those interested in the details: our SMD assembler Samsung SM421F is extremely fast and accurate as per the 0201 standard, the Asscon Vapor Phase solders even the most complicated SMT circuits without an error, and we monitor quality at every stage of the process with the AOI Mirtec MV-3L.

Do you have an idea for a new electronic product?

Great!

We have the knowledge, experience, creativity, experts and equipment needed for the implementation. Feel free to send us an inquiry, and we will get back to you and assess whether we can (and how we can) help you make it happen.

We curently own 15 international technology patents

15

Security is not a choice, but an obligation.

When you innovate, you have to invest – time, people, money, and sometimes patience…which is no small thing. That is why we never question maximum safety and reliability at all levels of research, development and production.

Process safety

All our business processes are compliant with and covered by the certificate of the ISO: 9001 standard. Our employees in the SMT assembly are certified according to the IPC-A-610 standard, the world’s most recognized standard for electronics assembly.

Security of innovation

No innovation is risk-free; therefore, reliable processes, as well as experienced and professional staff is of great importance. We regard our innovations and products as intellectual property and trademarks and protect them accordingly, and we are among those companies with the most internationally registered patents in the Republic of Croatia.

IPC

Our employees in the SMT assembly are certified according to the IPC-A-610 standard

Portfolio

Our state-of-the-art technological solutions and innovations are not the result of chance, but of many years of experience and work. For 15 years we have been designing and creating successful patents and innovations according to the highest standards. We are glad that our clients recognize us for just that – innovative solutions that make life and work easier.

Multipurpose laser parking system with interference and detection capability

Every driver will agree that safe driving is crucial. The human factor and potential mistakes can be significantly reduced with the help of state-of-the-art technology – and that is where we jump in! This multipurpose parking system incorporates many years of experience of our excellent engineers and programmers. It features the most accurate sensors, the fastest processing speed, comprehensive connectivity via Bluetooth and Wi-Fi, full vehicle coverage via connection with up to 7 sensors, wide angle detection and automatic shutdown option. The uniqueness of this product is our patented pulsed-laser beam detector with improved sun and temperature compensation. But our work does not stop there: regular firmware updates and impeccable customer support are always an integral part of our service.

Wildlife collision prevention system

In Europe, over half a million traffic accidents occur every year, in which, unfortunately, wild animals are also killed. All previous solutions have not been particularly effective, and we have developed this system to raise the level of safety: both for the driver and the wildlife. It is an electronic device hidden in a custom license plate. The device emits infrared light that is invisible to humans but visible to animals. Seeing this light will make them cautious, which will, in turn, modify their behavior and movement on the road. The technology is completely harmless to animals. It has dual emitters protecting both sides of the vehicle, GPS and a power-saving motion sensor, and features a plug-and-play installation. If more vehicles use this system, a cumulative protective effect is also achieved. The invention is protected by a pending patent PCT/E P2020/087728.

Machine Learning and AI for Radio Signals

Constant work and the desire for progress inevitably results in new knowledge, and in our case – new patents! We are constantly expanding our product portfolio, as evidenced by our latest innovation: a method for suppressing noise and increasing speed in miniaturized radio frequency detectors. The present invention is based on the ability of a receiver to extract a radio frequency signature, digitally process it and determine whether it is a valid signal, a signal of interest or a source of no interest to us. The addition of machine learning and artificial intelligence allows for better learning and classification of radar signatures in a dynamic database, which means the driver will only be alerted when needed.

About us

About us

A-Elektronik was founded in 2006 in Zagreb. From the very beginning, our ‘assembly’ has been of the engineering sort. We deal in electrical and electronic equipment, devices and components. We research, develop and produce.

PCB circuits, laser optics, capacitors, radars, SMD, SMT, chips, soldering irons and everything else that makes our everyday life continues to motivate us and encourage us to solve problems by constantly innovating. We owe our long-term success, recognizable quality and numerous patents to our excellent engineers in mechanical engineering, electrical engineering and computing, but also to partners who recognize quality – and are not afraid of challenges.

Contact us

Please feel free to contact us with any questions or inquiries you might have.